Improving onion shelf life – A transdisciplinary approach for technology creation and dissemination

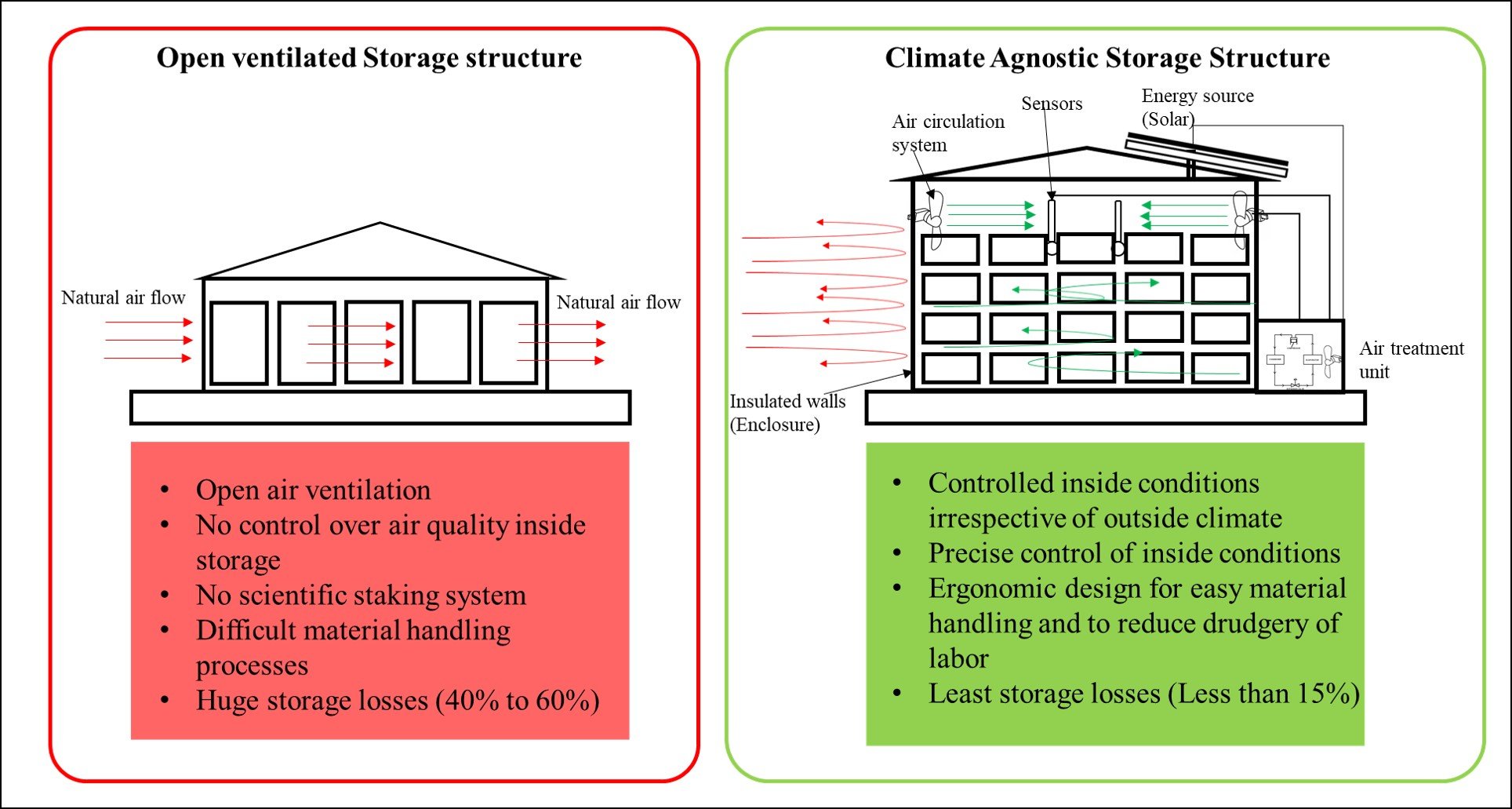

India with a population of 1.35 billion is the second largest producer of onion in the world (~25 Million MT in 2021). Over 70% of the onions are grown in the western and southern parts of the country. However, they are consumed across the country throughout the year. The imbalances in supply chain along with the high perishability of onions make the value chain inefficient. For the year-round consumption, onion is stored in traditional open ventilated storage structures where reported storage losses are in the range between 40 to 60%. The government is investing a large sum of money to stabilize the market prices through the construction of large sized open storage structures. Still, due to huge losses in traditional open structures, there is urgent need of affordable as well as scientific solution to this complex problem. With our research group at IIT Bombay, India, we addressed this issue by developing a storage technology with a transdisciplinary approach and came to very promising results.

What affects the shelf life of onions during the storage period?

Summer onions are harvested in the month of April, making up more than 60% of the total onion production. They are considered a good variety for storage compared to the winter and late winter season onions. Indian weather is driven by its monsoon cycle. Summer onions arrive for storage in the month of April and rain starts in June. So, weather changes rapidly in month of June and stored onions have to face high humidity as well as low temperature conditions. These conditions trigger the creation and propagation of bacteria and fungus in the onion which leads onions further towards rotting. Moreover, it results in sprouting of the onion which makes it further vulnerable to disease attack and additional water loss.

Along with the above-mentioned weather conditions, other reasons for the reduced shelf life are poor ventilation at the storage facilities. Due to heavy staking of onions in storage containers and poor ventilation mechanical damage occurs. The gases emitted by onions during storage can’t escape and further accelerates the process of onion deterioration.

Photographs showing the rotting of onions due to exposure to high humidity, poor ventilation and heavy staking inside the traditional open ventilated storage structure (pictures: Nilesh Vadgave).

Transdisciplinary nature of the problem

A major fraction of onion farmers are small holder farmers holding less than 1 hectare of land. The onion, being a cash crop, is a major source of cash flow for the families of those small holder farmers. Market fluctuations in prices directly affect their livelihood. On the other side, a significant fraction of retail buyers are low income households. Increased prices of onions due to shortages directly affect their food budget. Improving the shelf life of onions needs innovative approaches that are technological, affordable, accessible and appropriate for solving the problem. It involves science, technology, navigation of power relations of stakeholders in the onion market and understanding policies for driving decisions along the onion value chain. Therefore, solving the problem of post-harvest loss of onions calls for a transdisciplinary approach.

Climate Agnostic Onion Storage structure at CTARA, IIT Bombay

Research has shown that onion can be stored with minimum storage losses at controlled conditions near ambient conditions with a specified combination of temperature, humidity, air flow rate and other factors. Cold storages near zero temperature do not work with Indian conditions for many reasons. One of those reasons is the high ambient temperatures and the subsequent higher cooling costs associated with cold storages.

At Centre for Technology Alternatives for Rural Areas (CTARA)- IIT Bombay, we have developed a storage structure which keeps onion quality intact irrespective of the outside climatic conditions (hence called ‘Climate Agnostic!’). It circulates the conditioned air inside the storage enclosure to keep the inside conditions at specified levels. This ensures the reduction in unwanted weight loss of onion, its sprouting and rotting. It optimizes the system performance by allowing fresh air to mix with the recirculated air when outside conditions are closer to the storage conditions.

Comparison of traditional open ventilated storage and Climate Agnostic Storage for onion (Nilesh Vadgave)

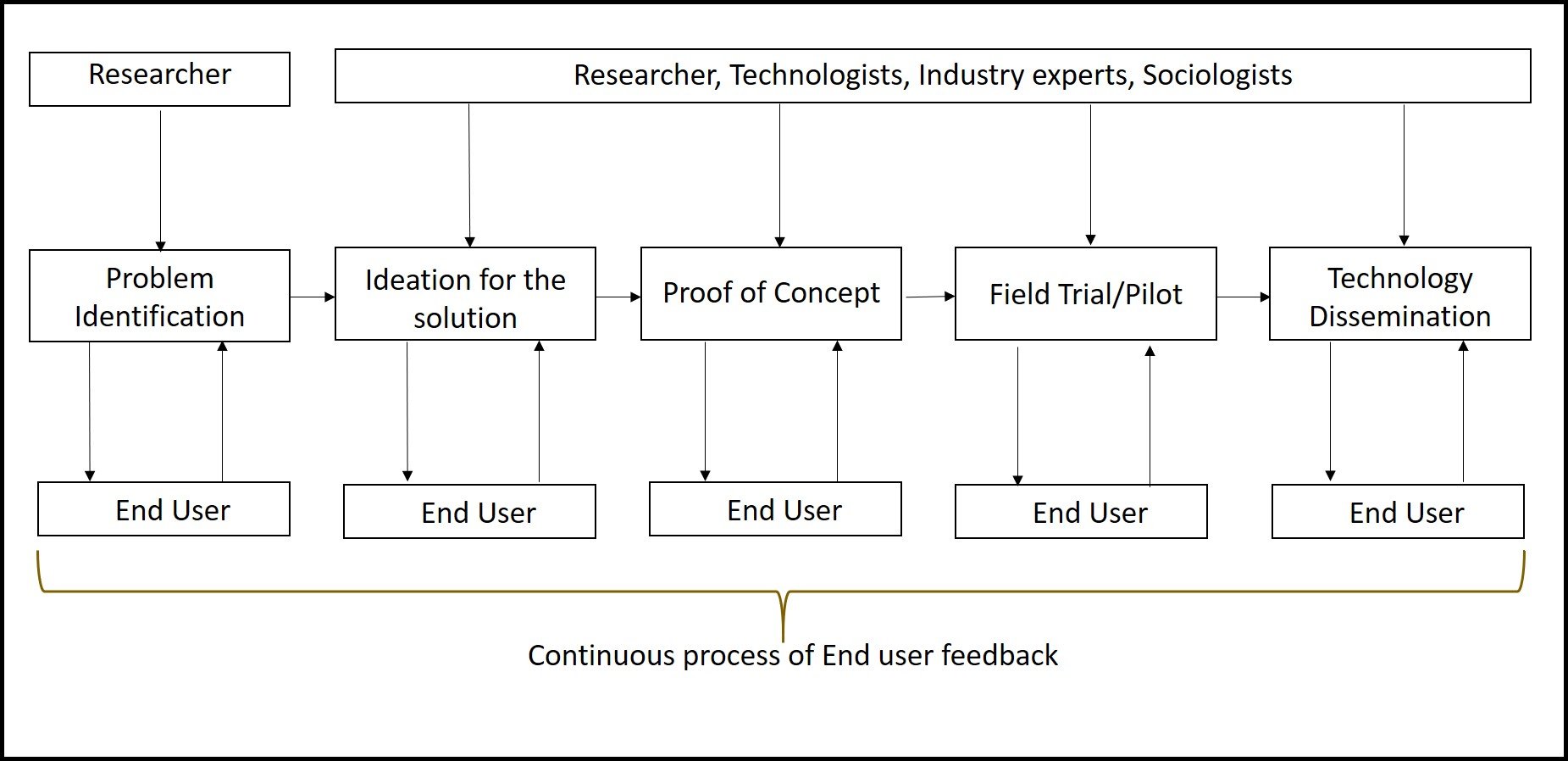

How involvement of end user’s feedback improves technology

Talking to the end users (farmers in this case) gave us important insights into choosing the right problems. After the proof of concept stage of the development, when we presented our storage technology to farmers, many of their queries and suggestions made us rethink and modify the design. For example, some farmers suggested to have an alternate source of electricity to reduce the dependence on uncertain on-grid electricity in some rural parts of India. The farmers’ suggestions played a key role in our technology generation because there are several aspects of the problem which technology would not solve alone. Hence, one needs to think of the entire system and all the stakeholders involved. They make a significant contribution to the success of the technological intervention.

Conceptual framework of co creation of technology in transdisciplinary research (Nilesh Vadgave)

If a technologically appropriate solution is not affordable to the end users, then it is still inaccessible! Hence, one major focus laid on optimising our solution for trade-offs between investment versus returns and reduced losses versus realised profits.

Feedback from the end users (farmers) at different stages of the process (pictures: Nilesh Vadgave)

The journey continues ...

The journey of improving the shelf life of onions through Climate Agnostic Storage structures continues and has now evolved to a ‘transdisciplinary co-creation of the technology’ from mere ‘engineering problem to be solved with few mathematical calculations’. Increasing engagement of the stakeholders (including end users) and their continuous feedback helps us to improve the technology every single day and is continuously offering us different lenses to look at the world!

ABOUT THE AUTHOR

Nilesh Vadgave is a doctoral candidate, studying technology development and social entrepreneurship at the Indian Institute of Technology Bombay, India. He studied mechanical engineering for his bachelor and did his post graduation in technology and development from IIT Bombay. This led him to develop a particular interest in development of intermediate technologies with social impact. He is currently working on the design and optimization of modular storage technologies to mitigate value chain losses in the perishable agricultural commodities. His transdisciplinary research integrates technology design and dissemination through participation of communities with the goal of ‘End to End Innovation’.

I would like to thank World Food System Centre at ETH Zurich to grant a scholarship to attend the short professional course on ‘Designing for Food system resilience: Circular approach’ where I received new knowledge and tools to analyse food systems from the lens of food security and solidarity economics to bring in circularity and resilience. I also express my thanks to Toya Bezzola for giving the opportunity to write a blog post and encouraging for the same.